The International Semiconductor Alliance (ISA) will be presenting state-of-the-art solutions for manufacturing and process optimization in the semiconductor industry at this year’s PCIM 2024 in Nuremberg. ISA members offer a unique combination of technical expertise and comprehensive services covering the entire manufacturing chain from assembly to quality analysis. This knowledge can be used by customers in two recently established application centers in Berlin.

“Our customers can rely on a holistic, comprehensive manufacturing concept that covers all sub-processes in packaging technology, from die attach, housing to inspection and quality analysis,” explains Daniel Schultze, Managing Director of Tresky GmbH. Tresky GmbH is a founding member of ISA alongside budatec GmbH and Nanotest & Design GmbH. Bond Pulse by Dr. Aaron Hutzler is also part of the alliance.

The mission of ISA is to offer cross-process support and consulting services to ensure an efficient, reliable and reproducible manufacturing process. Therefore two application centers have been set up in the north-west and south-east of Berlin to offer customers comprehensive support in process development for prototypes. At the same time, both centers can also be used for production on behalf of customers. “As a contract service provider, we offer our support in the prototyping phase as well as in the production of small series or batch size 1. This enables rapid production on demand. Our customers don’t have to establish their own production capacities or interrupt existing series production,” says Schultze.

“Our engineers support our customers in the implementation of their packaging technologies and partner with them to derive the optimum process selection and parameters for the production of their end products,” continues Schultze. Based on the end product, the production volume and the given cost framework, the ISA member companies develop proposals for process developments as well as structural and process optimizations in order to reduce costs and shorten the time to market. The two application centers also carry out feasibility studies with a final professional evaluation.

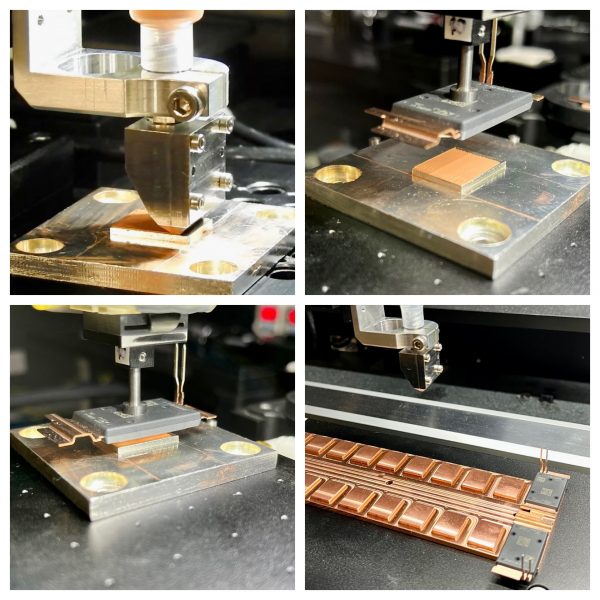

Schultze also emphasizes that the application centers are also available to anyone who would like to have process evaluations or a pure process demonstration. ISA offers these individual demonstrations and feasability studies to showcase the performance of the solutions. All common bonding technologies such as adhesive, soldering or sintering can be carried out in the application centers. For subsequent validation, ISA uses appropriate measurement technology such as X-ray, C-SAM or cross-sections. Once the evaluations and feasibility studies have been completed, ISA supports customers and interested parties in the project planning and management of the manufacturing process.

ISA and its member companies will be presenting their product and service portfolio at PCIM Europe in Nuremberg from June 11 – 13 in Hall 5, Stand 402.